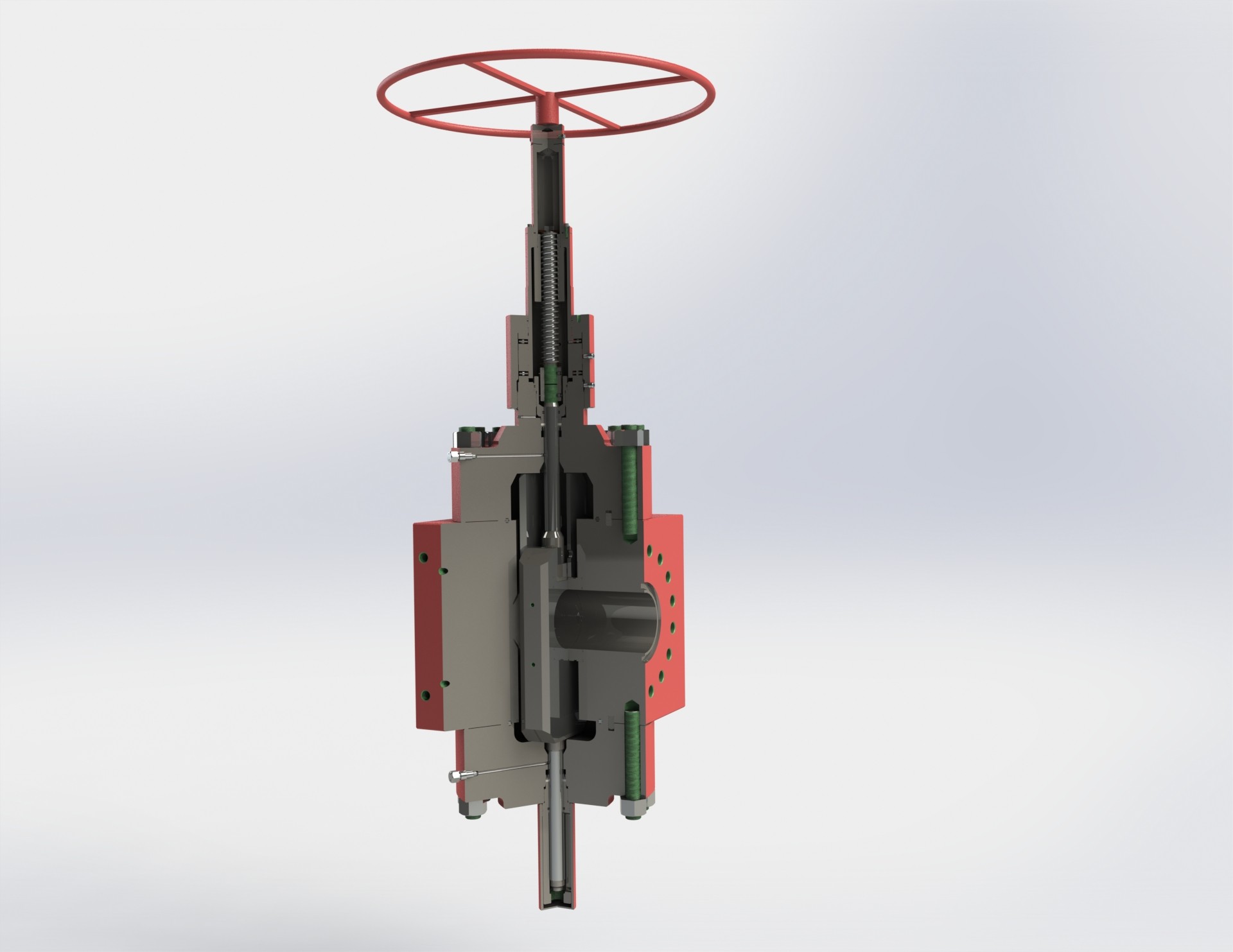

FLS-R Large-Bore HP API 6A Gate Valve

查看更多

Overview

Advantages

Simple, reliable gate and seat design that promote ease of field service and minimal spare parts inventory

Unique ball-screw design that allows for rolling friction in place of sliding friction

Bidirectional design that provides flow direction versatility and increased service life

Seal diameters and bearing areas of the seats that prevent trapping of pressure inside the valve cavity

Lower stem that balances pressure thrust on upper stem to reduce operating torque, which prevents body cavity pressure buildup during operation and provides position indication

Metal-to-metal stem backseat on both the balancing stem and valve operator stem for replacement of either stem seal with the valve cavity under pressure

Backseat that can be energized to isolate the stem seal stuffing box from line pressure and the grease fitting port used to test the backseat integrity

Two spring-loaded, pressure-energized, nonelastomeric lip seals for maximum protection against intrusion of particle contaminants into the valve cavity

Seals that improve gate and seat service life, prevent damage to the body seat seal face, and improve valve performance at very low pressures

Metal-to-metal sealing at the gate-to-seat and seat-to-body seals

Forged body